Opcenter Production Scheduling Case Study: Applied Composites

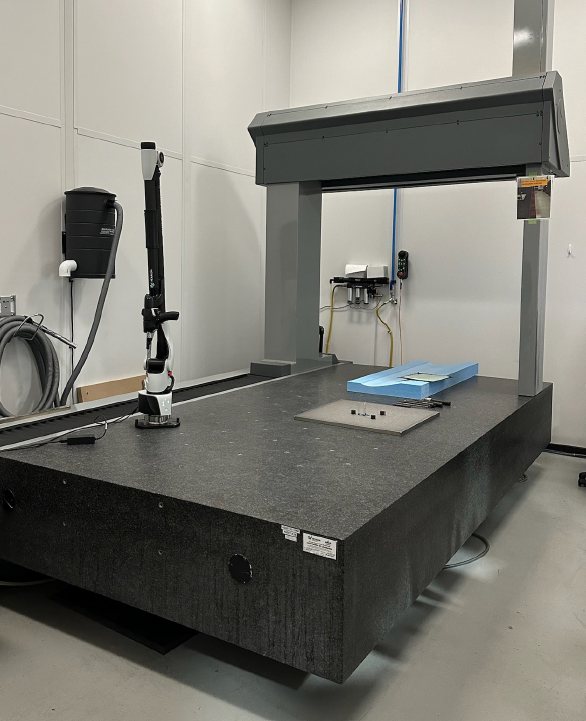

Check out our latest Opcenter Production Scheduling success story featuring Applied Composites, a global leader in the aerospace composites industry. In this case study, you’ll see the remarkable impact that an APS solution has on scheduling precision, resource optimization, and overall productivity.