Opcenter (Preactor) Planning & Scheduling Software

by Manufacturing & Industry

Opcenter (formerly Preactor) Advanced Planning and Scheduling software is flexible enough to be used in a wide range of industries to optimize production, enabling the Planner to make better decisions and react quickly to changes. Opcenter APS can be standalone or integrated with a wide range of ERP/MES systems.

Opcenter is used by Aerospace & Defense companies who make parts and assemblies as well as the final aircraft, typically categorized by small batch sizes but very complex routing and material requirements.

Opcenter is used right across the Automotive and Transportation sector from parts suppliers to OEM final assembly of the finished product.

Opcenter is used throughout the Chemicals, Oil and Gas supply chain including the manufacture of equipment for the exploration and extraction process, transport logistics, and the production of final end products.

Opcenter is widely used in the Electrical Equipment and Electronics sector. It ranges from mass production of PCBs through to small batch simple and complex assemblies.

The Food & Beverage Industry faces unique demands. Opcenter is very commonly used in the food sector for a wide range of applications from long term strategic planning, medium term tactical planning and detailed scheduling.

Opcenter is used by companies in the Glass, Ceramics and other materials sectors, from quarried aggregates to magnetic tapes.

In the Machinery and Equipment industries, Opcenter can generate a schedule based on deep bills of material whereby parts, sub-assemblies and final assemblies are often generated to order.

Opcenter is used widely in the metal processing and fabrication sectors from foundries to continuous casting of billets, from wire making to forging.

Opcenter is used widely in the Packaging sector for contract packaging and printing to boxes, cartons and healthcare product packaging.

Opcenter is used widely in the Pulp and Paper sectors. Printers can have various capabilities in terms of colours and alternative routes for orders to take.

Opcenter is used by many companies in the Pharmaceuticals, Life Sciences and Cosmetics sectors both during development of new products and in planning and scheduling production.

Opcenter is used in Precision Engineering, manufacturing complex tools with multiple parts, where a large portion of the overall manufacture is assembly.

In the Rubber & Plastics industries, Opcenter optimizes sequence of batches onto machines based on resin type, color and other attributes by reducing changeover time.

Opcenter is used by many companies in the Textiles sector, from manufacturers of apparel and shoes to automotive fabrics.

Opcenter is used by companies in the Transportation, Logistics and Services sectors, from shipping and distribution centers to passenger management.

Opcenter has been implemented widely in the furniture and wood processing sectors for both straightforward and complex processes of assembly.

Easily Integrated

No matter your ERP, Opcenter APS easily integrates with its built-in API...

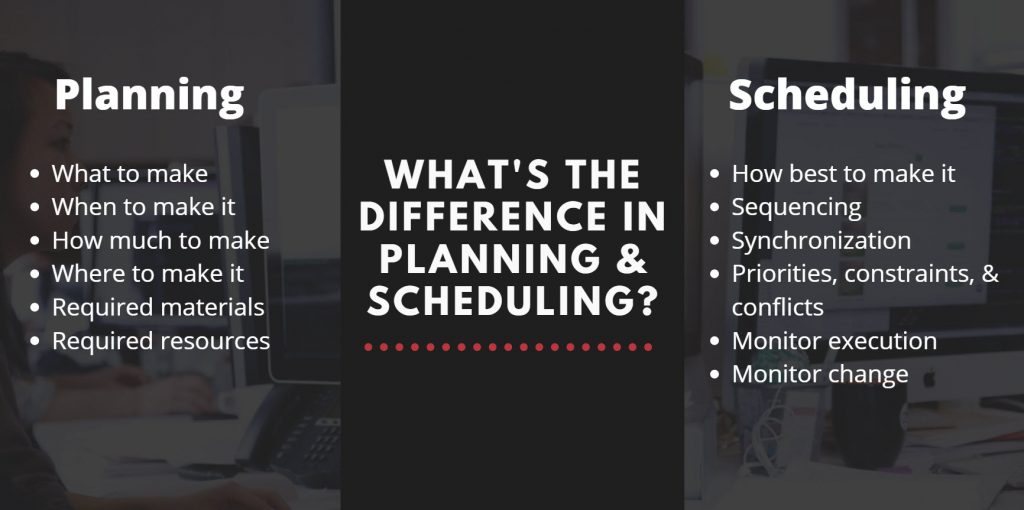

Advanced Planning

Advanced Scheduling