experience matters

The right partner. The right solutions.

You've come to the right place

As part of the ATS Global family with offices in more than 25 countries, Lean Scheduling International (LSI) has been implementing Advanced Planning & Scheduling Solutions for over 25 years. We have helped some of the world’s most innovative manufacturers react faster and smarter to change by providing custom configuration & integration of APS production scheduling software alongside their existing ERP solution. By partnering with LSI, clients confirm greater visibility, improved on-time delivery, reduction in inventory levels, & greater overall profitability. We can help you too.

With over 170 years of combined experience, LSI's team of technical & sales experts can help you diagnose and implement the production scheduling solution that works for you.

With product offerings in planning & scheduling, quality management, and forecasting, LSI is Siemens' #1 Opcenter APS implementation partner in North America

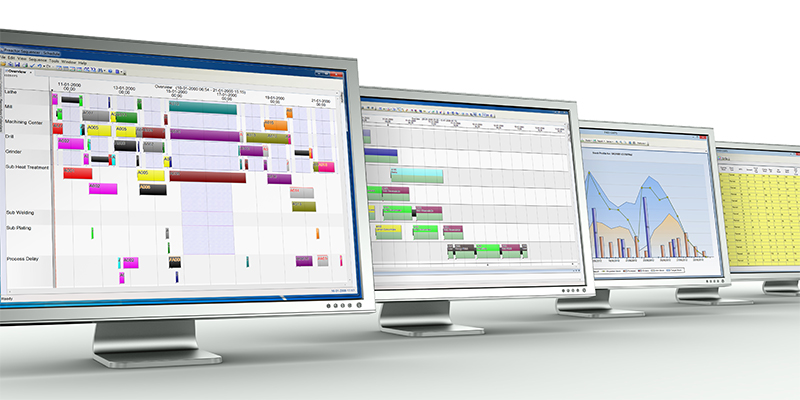

What is Advanced Planning & Scheduling Software?

In today’s global economy, it is vital for manufacturers to have an edge over their competition in order not just to survive, but to thrive. Companies are constantly searching for ways to become more efficient and be the best in the market. We firmly believe that without an Advanced Planning & Scheduling Solution, or APS for short, they will never truly achieve this goal. APS software is designed to improve the synchronization of your manufacturing processes, giving you greater visibility and control to increase utilization and on-time delivery, while reducing inventory levels and waste.

APS In Action...

Opcenter APS Preferred Sequence

Opcenter APS Drag & Drop Functionality

Opcenter APS Calendaring

Why do clients choose LSI to implement APS? The power is in numbers...

Some of our APS Clients...

Manufacturers of all sizes in all industries can use Advanced Planning & Scheduling

Committed to helping our clients succeed with their Production Scheduling

How we work with you

Two Day Assessment

Explore all aspects of scheduling in your organization and how they impact your business

See more about our Two Day Assessment

System Design

Takes the findings from the assessment and details the plan of attack

Configuration

An iterative modelling process where the design is executed and fine-tuned

Integration

Building connections to virtually any ERP, MES or other database/data collection system

Testing

With our hands-on workshops, the entire team is involved in testing, data validation, and functional testing

Deployment

Team involvement from all areas of the company from the start results in a smooth cutover, significantly reducing the risk involved in implementing a production dependent scheduling system.

Post Implementation Support

Long after your project has launced, we stand by you to ensure that you continue to reap the benefits of your system year after year

Considering an APS Solution?

How To Get Started

Free Discovery Consultation

We meet with you to hear your story and determine if our solutions would be a fit for your needs

Deep Dive & Demo

Through the findings in the discovery process, we build a demo to help you understand functionality & feasability

Two Day Assessment

Our team comes on site to begin the process of evaluating your existing systems and helps you understand your options, with a proposal to follow

How do you want to take the next step with us?

Don’t take it from us…

Here's what our clients say