Smart Inventory Optimization

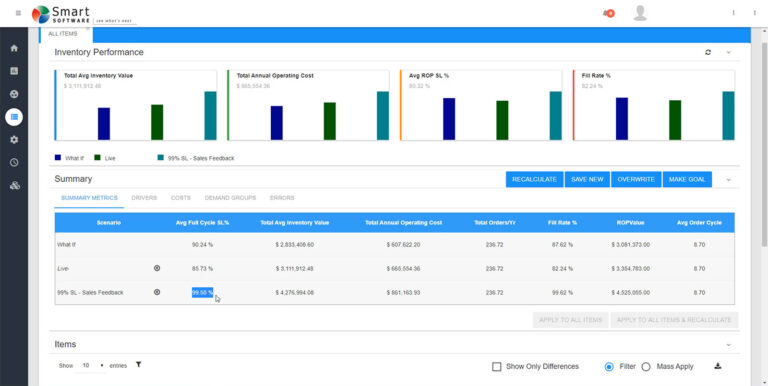

Smart Inventory Optimization™ is a collaborative inventory planning and optimization solution. The solution delivers inventory policy decision support and the means to share, collaborate, and track the impact of your inventory planning policy. This can help realize millions in savings by improving customer service and reducing excess stock. You can forecast metrics such as service level, fill rate, holding costs, ordering costs, and stock out costs. Users can identify overstocks and understocks, adjust stocking policies when demand changes, share proposed policies with other stakeholders, collect feedback, and establish a consensus inventory plan.

Smart Inventory Optimization

Keeping inventory investments in check while maintaining high customer service levels is a constant balancing act. Without proper controls, excess inventory grows throughout your supply chain, locking up vital working capital that constrains your company’s growth. Every day, the ERP system makes purchase order suggestions and manufacturing orders based on planning drivers such as safety stock, reorder points, and Min/Max levels. Ensuring that these inputs are understood and continually optimized will generate substantially better returns on your inventory assets. Unfortunately, many organizations rely on rule of thumb logic, institutional knowledge, and “one-size-fits all” forecasting logic that assigns all items within a particular group the same service level target. These approaches yield suboptimal policies that cause inventory costs to balloon and service performance to suffer. Compounding the problem is the sheer volume of data – thousands of items stocked at multiple locations means planners don’t have the bandwidth to proactively review these inventory drivers on a regular basis. This results in outdated reorder points, safety stocks, order quantities, and Min/Max settings that further contribute to the problem.

With Smart Inventory Optimization, you can:

- Identify where you are overstocked and understocked.

- Modify planning parameters based on your business rules, service targets, and inventory budget.

- Leverage the optimization logic in SIO to prescribe planning parameters and service levels for you.

- Compare proposed policies to the benchmark.

- Collaborate and develop a consensus inventory plan.

- Automatically generate revised planning parameters as demand and other inputs change.

Optimal Inventory Levels

- Reduce excess stock

- Improve service levels

- Minimize buyer transactions

- Maximize return on assets

Inventory Management

- Balance service levels

- Identify stockout risk

- Identify overstocks

- No finger-pointing

Actionable Analytics

- Align process with strategic objectives

- Empower team to “make it so”

- Optimize as conditions change

- Pass results to ERP

Who is Inventory Optimization for?

Smart Inventory Optimization is for executives and business savvy planners who seek to:

- Yield maximum returns from inventory assets.

- Address the problem of highly variable or intermittent demand.

- Broker the service vs. cost tradeoffs between different departments.

- Develop a repeatable and efficient inventory planning process.

- Empower the team to ensure operational plan is aligned with strategic plan.

What Questions can Inventory Optimization Answer?

- What is the best service level achievable with the inventory budget?

- What service levels will yield the maximum return?

- If lead times increased, what would it cost to maintain service?

- If I reduce inventory, what will the impact on service be?

- If order quantity increases, what will the impact on service and costs be?

- What is the order quantity that balances holding and ordering costs?

Inventory Forecasting for the Inventory Executive

Smart Inventory Optimization empowers you to:

- Predict service performance and inventory costs.

- Assess business impact of “what-if” inventory policies.

- Align inventory policy with corporate strategy.

- Establish an operational framework that guides the planning team.

- Reduce inventory and improve service.

Want to see the Demo?

Let us answer those questions you have

Inventory Management Culprits

What are the real causes of inventory excess and stock outs? This video explains that it’s more than unpredictable demand and supply and outlines what companies should consider when deciding what to do about it.