LEAN and APS – A Clear Vision

How APS is Helping Lean to Handle Volatility and get more Visibility

How APS is Helping Lean to Handle Volatility and get more Visibility

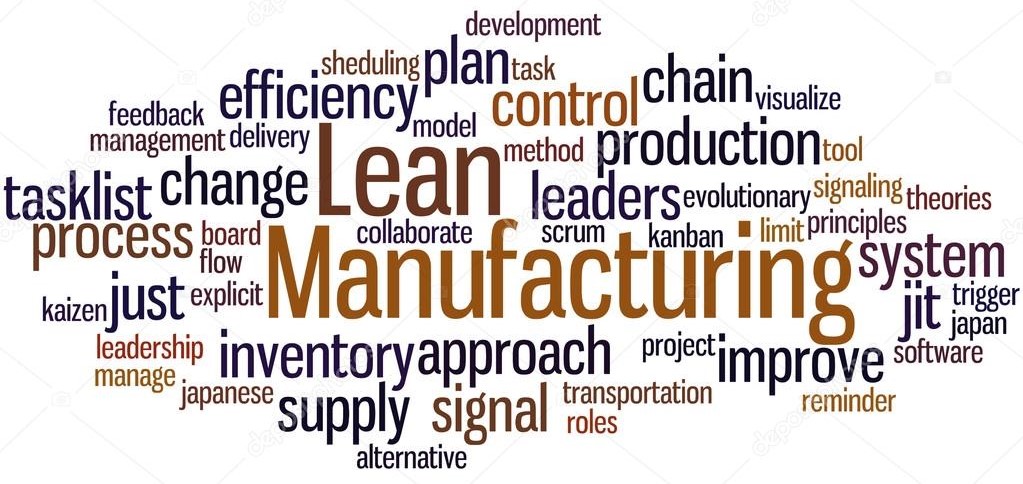

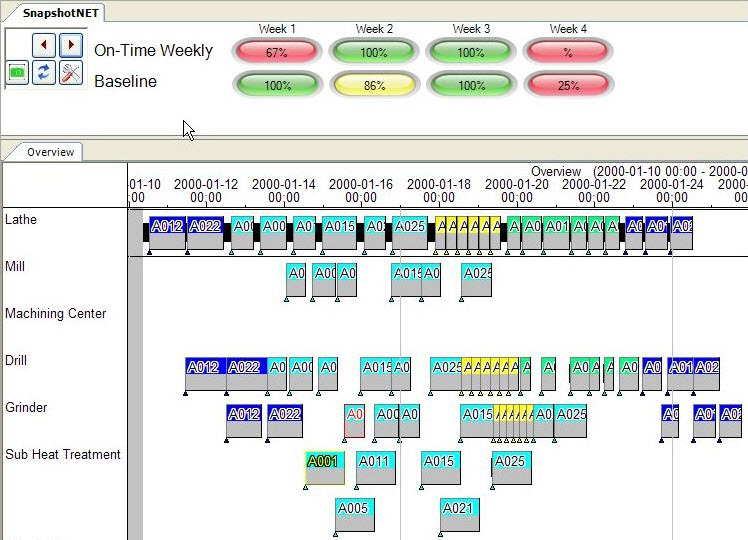

How time buckets limit ERP’s ability to do resource planning

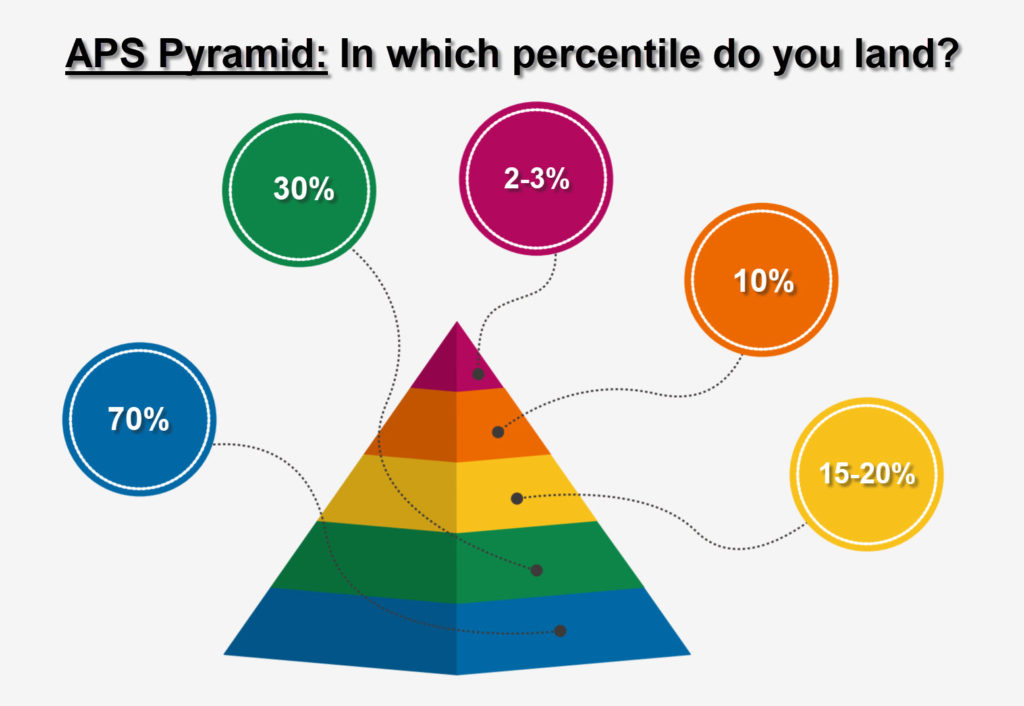

Despite the fact that many Advanced Planning and Scheduling (APS) systems fail miserably, manufacturers are starting to understand that this exciting technology is starting to deliver phenomenal results. It appears that those who successfully implement APS go on to reap exceptional rewards and dominate their competition.

At LSI, we use the APS Pyramid to help clients understand how they are using APS compared to what others are doing. This is very useful for companies who have achieved some success but are ready to go to the next level.

Many experts now understand that ERP systems do not have the functionality required to create a valid finite capacity schedule. But many of these experts have glossed over the severe limitations of the planning module that converts customer demand into the projected consumption of plant capacity.

I would imagine that many readers of this article have been through the acquisition and implementation of one or more ERP systems. ERP vendors will confidently assert that their system will do anything and everything except maybe, make the coffee.

Why ERP planning negates LEAN when managing increased levels of CHANGE

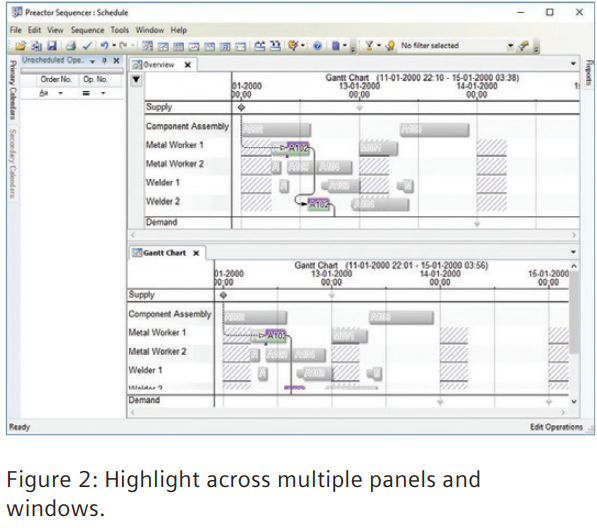

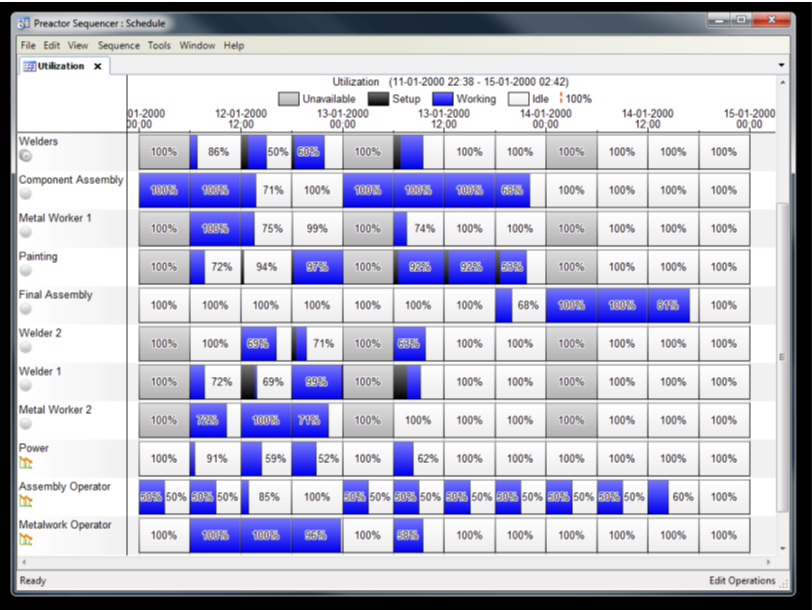

In Preactor AS, the Operation Properties functionality has been expanded upon, introducing the Operation Display Colors pane and the ability to create Operation Property Profiles. Created profiles can display a wide range of information, and allow for all sections of an operation bar to be modified.

The following is a summary of new features/functionality released in the Preactor product from version 12 through version 16.5.

Project Management (PM) software such as Microsoft® Project can be an invaluable tool for managing mid to long-term projects in industries such as construction. But this does not necessarily work across of industries although many managers have attempted (unsuccessfully) to adapt PM software to the world of production scheduling.