More than ever, manufacturers need to be more eco-friendly and reduce their impact on the environment. With growing concerns about climate change and resource depletion, many industries are exploring innovative solutions to make their operations more eco-friendly. ATS Lean Scheduling can assist you with selecting the right production scheduling software. We provide expert guidance and resources to help you choose a tool that meets your needs and delivers the results you want. One such tool is Opcenter Scheduling software. But how can this software help the environment?

Understanding Opcenter Scheduling Software

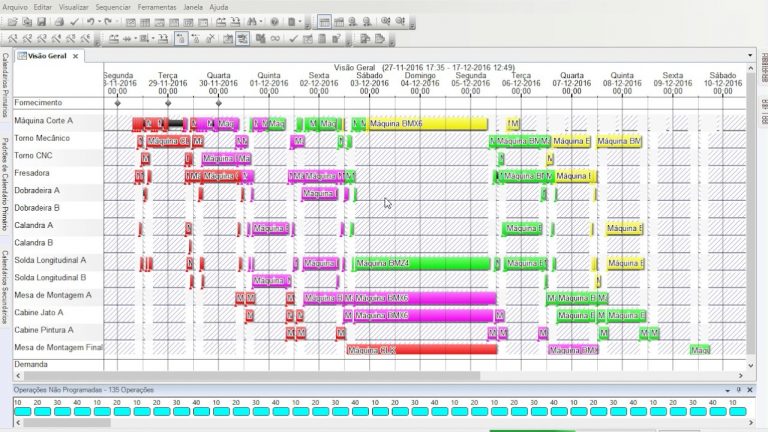

Opcenter Scheduling is an advanced scheduling tool that improves how manufacturers manage production. It helps them plan and organize schedules better, making sure resources are used wisely and waste is reduced. By giving a clear view of the production process, Opcenter software helps companies streamline their operations and make smart, data-based decisions.

Real Benefits of Production Software In Environment

- Reducing Waste Through Better Planning

Opcenter Scheduling software helps cut down on waste by improving planning. Traditional production often leads to overproduction and excess waste, but Opcenter creates accurate schedules that match production with actual demand. This prevents making more products than needed, reducing both material waste and the energy used in manufacturing.

- Improving Resource Efficiency

Opcenter also helps use resources more efficiently. It provides a clear view of production processes, allowing companies to use materials, machinery, and labor more effectively. The software helps spot and fix production problems, making sure machines run smoothly and reducing idle time and energy use.

- Lowering Energy Consumption

Energy use is a big part of manufacturing’s environmental impact. Opcenter can help lower energy consumption by scheduling production runs during off-peak hours when energy is cheaper and less demanding on the power grid. Better production efficiency and reduced downtime also mean less energy is needed to run and maintain machinery, cutting the overall energy footprint.

- Enhancing Supply Chain Sustainability

Opcenter improves supply chain sustainability by offering real-time updates on shop floor production. This helps companies work better with suppliers, reducing the need for urgent shipments and last-minute orders that increase carbon emissions.

- Supporting Continuous Improvement

Opcenter provides detailed data and reports that help companies track their environmental progress and find ways to improve. By regularly reviewing production data, businesses can keep refining their processes to be even more sustainable.

Conclusion

Opcenter Scheduling software offers a range of benefits that contribute to reducing the environmental impact of manufacturing operations. From minimizing waste and improving resource efficiency to lowering energy consumption and enhancing supply chain sustainability, this advanced scheduling tool plays a crucial role in promoting greener practices. As businesses grow to meet their environmental goals, adopting Opcenter Scheduling software can be an important step toward a more sustainable future.

Reach out to us today to discover more about how production scheduling software can give your business an edge in the fast-paced manufacturing industry.