Category: APS

LSI .

Take a break and read all about it

Opcenter APS 2410: What’s New in the Latest Release?

We are excited to announce that the new version of Opcenter APS has been released by Siemens Digital Industries Software! See what’s new in version 2410.

The Impact of APS Software on Lead Time Efficiency

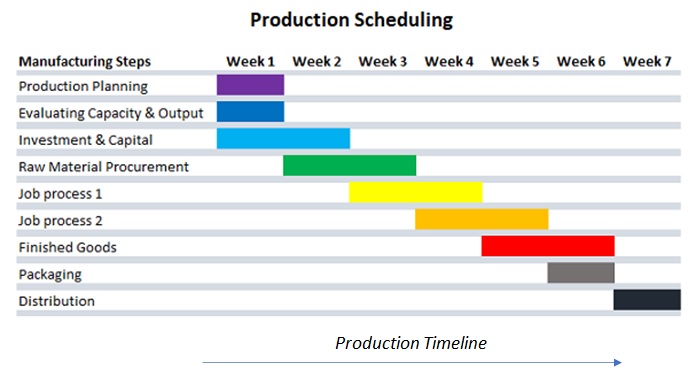

To win in the competitive race, businesses are constantly seeking ways to improve efficiency and increase customer satisfaction. One significant factor in achieving these goals is making sure timely delivery of products. Fortunately, Advanced Planning and Scheduling (APS) software provides a powerful solution for streamlining production and significantly reducing lead times.

New Release: Opcenter APS 2404

We are excited to announce the release of Opcenter APS version 2404, the latest upgrade in Siemens’ suite of advanced planning and scheduling (APS) solutions.

Boost Production Efficiency with Manufacturing Planning Software

Don’t just invest in software, leverage its power to transform your manufacturing operations with Manufacturing Planning Software.

Opcenter APS 2310 is Now Available!

We are happy to announce that Opcenter APS 2310 is now available! This latest release by Siemens Digital Industries Software has exciting new features & capabilities. Check out the notes below that will fill you in on all of the highlights.

7 Signs Manufacturers May Need an APS Software Solution

From our 25+ years in experience, here are the 7 signs indicating manufacturers may need an APS software solution.

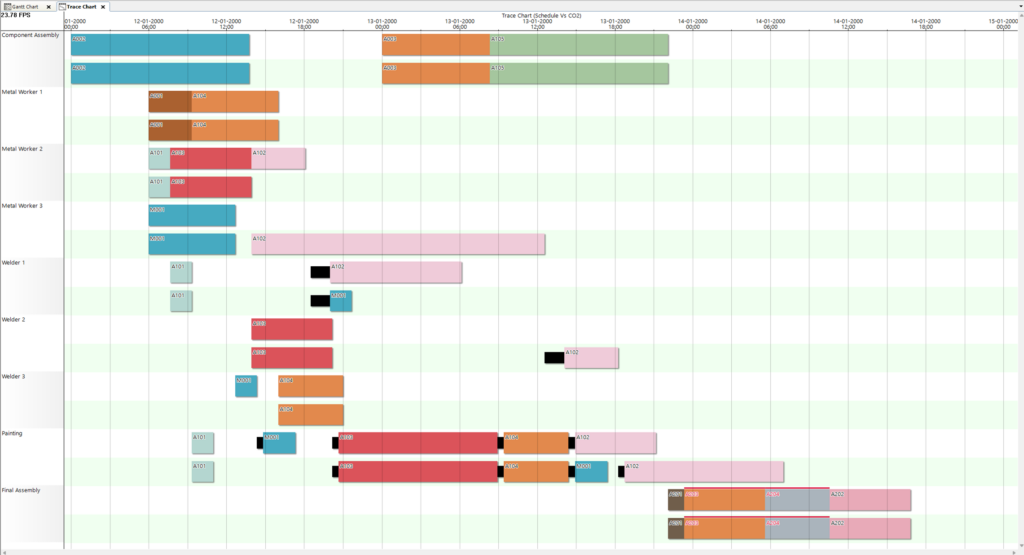

Finite Capacity Scheduling for Manufacturing Production

This post breaks down the concept of Finite Capacity Scheduling (FCS). By considering resource constraints and real-time information, FCS aims to increase efficiency, reduce costs, and improve customer satisfaction.

New Opcenter APS Case Study: Koch Foods

Dive into the details of how LSI collaborated with Koch Foods, Inc. to develop a production planning & scheduling solution that addressed limitations and improved operational efficiency by considering factors such as allergens, setup requirements, shift patterns, machine capacity, and material availability.