What is APS Software?

APS

Advanced Planning & Scheduling

In today’s global economy, it is vital for manufacturers to have an edge over their competition in order not just to survive, but to thrive. Companies are constantly searching for ways to become more efficient and be the best in the market. We firmly believe that without an Advanced Planning & Scheduling

Solution, or APS for short, they will never truly achieve this goal. APS software is designed to improve the synchronization of your manufacturing processes, giving you greater visibility and control to increase utilization and on-time delivery, while reducing inventory levels and waste.

Signs that Your company needs an APS solution

High WIP & Stocks

Low Productivity

Delays & Breaks

Missed Delivery Dates

Advanced Planning & Scheduling

How APS Works

Your Reality

Many planners & schedulers spend stressful hours every day in their spreadsheets to produce schedules that are already useless by the time they are released because of changes that have happened during the process. Machine breakdowns, labor constraints, delayed purchase orders… we know just how frustrating this is, but this is how the real world operates! It is important to reduce the manual effort required to create and modify your schedule when change is needed. Our APS solutions give you explicit impact analysis and the ability to manage change quickly & easily.

APS Functionality

Creating a production schedule is more than just saying, “Here is what we are going to do, so let’s get to work!” There are many variables that effect the schedule. An accurate schedule is dependent on reflecting your shop floor realities by considering the finite capacity of your resources such as machines, labor, tools, and materials. You will also have the ability to simulate various “what-if” scenarios to find solutions that seek to minimize costs, leads times, inefficiencies, & inventory. Our APS solutions are designed to reflect these realities and stays fresh by seamlessly integrating with the data in your existing systems (ERP, MRP, MES, etc.).

The Actual Benefits of APS

By creating schedules that are current & accurate, you will achieve greater efficiency throughout your production process. More insight leads to less stress and better decision making! Not only will you be able to manage change as it happens, but you will achieve greater overall visibility, on-time delivery performance, improved customer service, inventory reduction, cycle time reduction, a boost in productivity, and overall profitability!

Expected Results...

APS In Action...

Opcenter APS Preferred Sequence

Opcenter APS Drag & Drop Functionality

Opcenter APS Calendaring

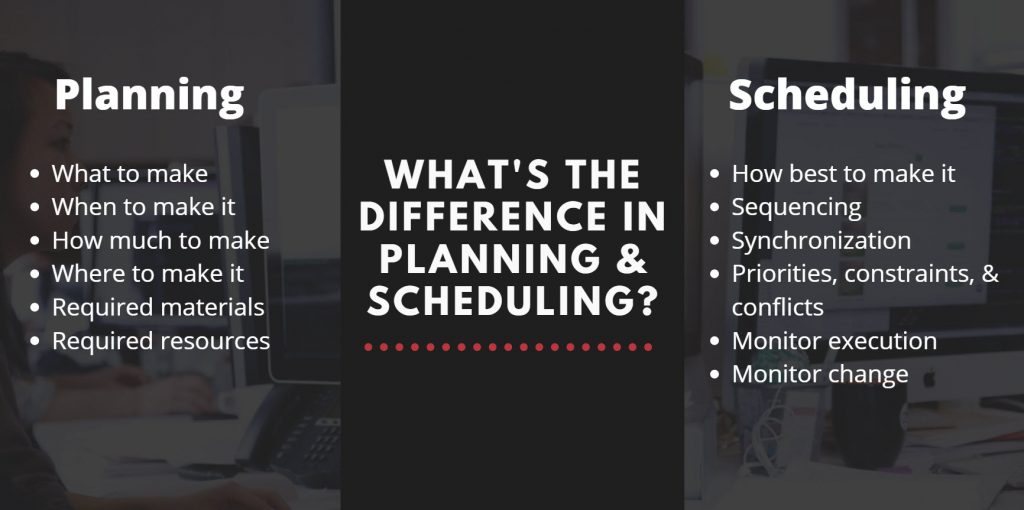

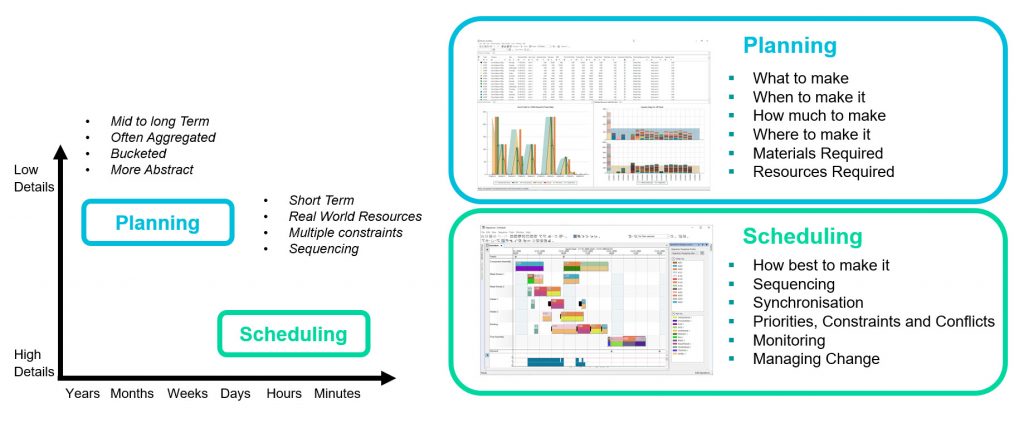

So, What's the Difference in Planning & Scheduling?

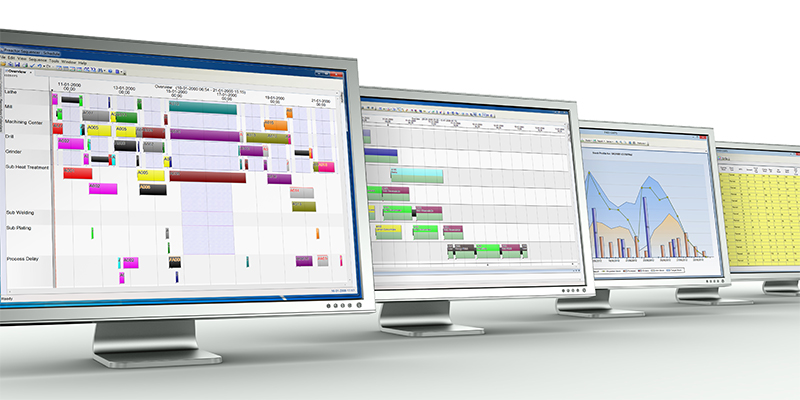

The basic difference between planning software and scheduling software is that planning systems are bucketed (monthly, weekly, daily) and cannot preserve operation sequences within the time bucket. True scheduling systems are bucketless, preserving sequencing, and capable of generating work-to or dispatch lists. Assigning an operation to a resource is a key function for achieving operational efficiency and optimizing performance. Detailed scheduling uses a shorter time horizon and a much more detailed process route than a planning system.

Advanced Planning is a strategic decision support tool that combines forecast and long-term orders that target stock levels and bucketed resource capacities to ensure that future demand is met. Planning can be executed in finite or infinite capacity mode, and planning time periods can be days, weeks, months, or a combination of all three. If used together with the scheduling system, detailed production schedule information can be sent back to the planning system and this will override planned volume with scheduled volume. The master production schedule (MPS) can then be recalculated using the production schedule as the base for new results. For more on forecasting options to feed the planning tool, check out Forecast Pro.

Advanced Scheduling is a finite capacity tool based on a detailed model of the plant. It takes into account the actual availability of resources and considers multiple constraints to produce an achievable schedule. It is a scheduling tool primarily for manufacturers that need to schedule machines, production lines and resources, but is also used in services and logistics. Typically, the input is manufacturing orders that have a process route associated with each one, defining the operational steps to make the product. The user then can load the orders onto individual resources using scheduling rules and interacting with the schedule using the Gantt charts and generated plots. A typical output would be a dispatch list for each resource.

Easily Integrated

No matter your ERP, Opcenter APS easily integrates with its built-in API...

LSI's proven Implementation Process

While no two advanced planning & scheduling software solution implementations are exactly the same, we have a proven process for working with clients. Find out more about this process and how we work with you.