Opcenter (Preactor) Scheduling

Siemens Opcenter Advanced Scheduling (formerly Preactor) software is an interactive, multi-constraint, finite capacity production scheduling system that provides support for decision making for overtime, order prioritization, production batches, due date negotiation, and order processing.

Interactive, multi-constraint, finite capacity manufacturing production scheduling...

Siemens Opcenter (Preactor) Advanced Scheduling software is an interactive, multi-constraint, finite capacity production scheduling system for manufacturers. Availability of resources and additional constraints such as tooling and materials are all taken into consideration during scheduling to ensure an accurate model of your environment. Orders can be scheduled quickly using intelligent built-in rules, and the planner also has the ability to manually interact with the schedule to make changes based on their experience or new information, including drag-and-drop functionality.

Siemens Opcenter (Preactor) Advanced Scheduling provides decision making support for overtime, order prioritization, split production batches, due date negotiation, and order processing.

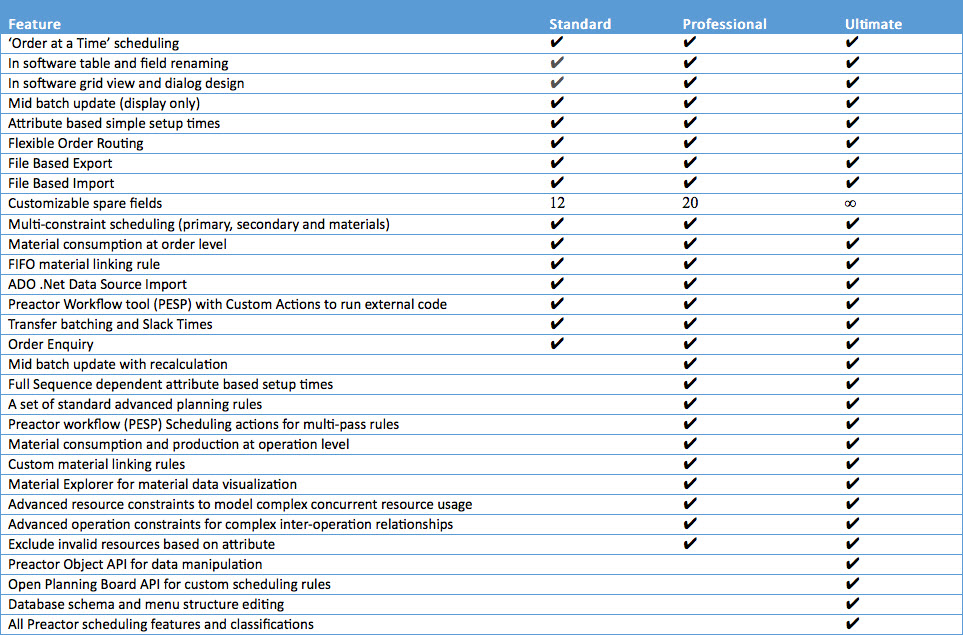

There are currently three product levels for Siemens Opcenter (Preactor) Advanced Scheduling: AS Standard, AS Professional, & AS Ultimate. For a breakdown of each, please have a look at the video & comparison chart below.

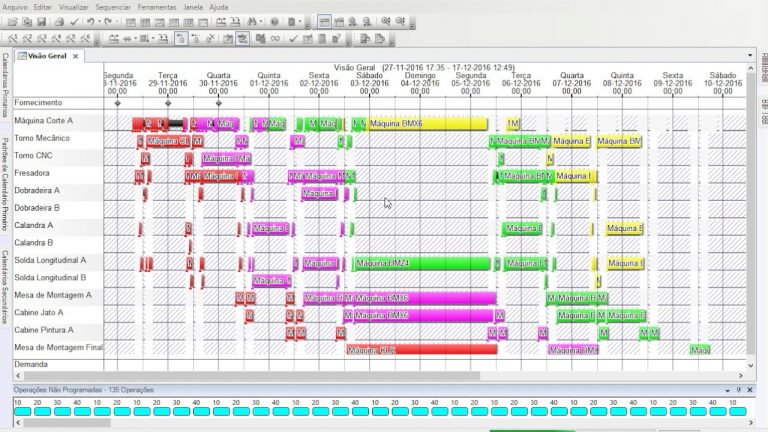

Visualization of the sequencing gantt chart within Opcenter (Preactor) Advanced Scheduling

Opcenter Scheduling

Materials, tools, & operator constraints

- Multiple constraints with finite capacity

- Material availability

- Tooling & special equipment

- Operator allocation to operations

- Enable/disable constraints for analysis purposes

Accurate & reliable production scheduling

- Higher process adherence & better performance

- Higher customer satisfaction (on-time delivery)

- Increased visibility & collaboration

About Opcenter APS...

Faster

Schedules in minutes

Heuristic approach

Frequent reschedule

Deviation management

Quick problem detection

Smarter

Graphical tool

Cause & effect analysis

Frequent reschedule

Identify problems

Fix issues before they happen

Effective

Improved customer service rate

Productivity increases

Inventory reduction

Cycle time reduction

Fast return on investment

Flexible

Configurable workspace

Flexible data structure

Full API (programming interface)

Integrated reporting tool

Unattended scheduling

Flexible sequencing by constraints

Scalable

Integrates to your current systems

Solution evolves with your company

Part of a family of products

From Small/Mid-Size to Fortune 500

Adopted Worldwide

Technically superior

Multi-language

Seamless integration

Global support

Largest install base of any APS

Signs that Your company needs an APS solution

High WIP & Stocks

Low Productivity

Delays & Breaks

Missed Delivery Dates

Advanced Constraint Modeling (Professional)

Advanced Material Handling

Development Environment (Ultimate)

Order Based Multi-Constraint Scheduling (Standard)

Advanced Schedule Optimization (Professional)

Assembly Process Visualization (Professional)

Interactive Schedule Viewing (Ultimate Viewer)

Easily Integrated

No matter your ERP, Opcenter APS easily integrates with its built-in API...

Opcenter Scheduling In Action...

Opcenter APS Preferred Sequence

Opcenter APS Drag & Drop Functionality

Opcenter APS Calendaring

Some of our APS Clients...

Manufacturers of all sizes in all industries can use Advanced Planning & Scheduling

Expected Benefits...

Opcenter Scheduling

Product Features & Level Comparison

How do you want to take the next step with us?

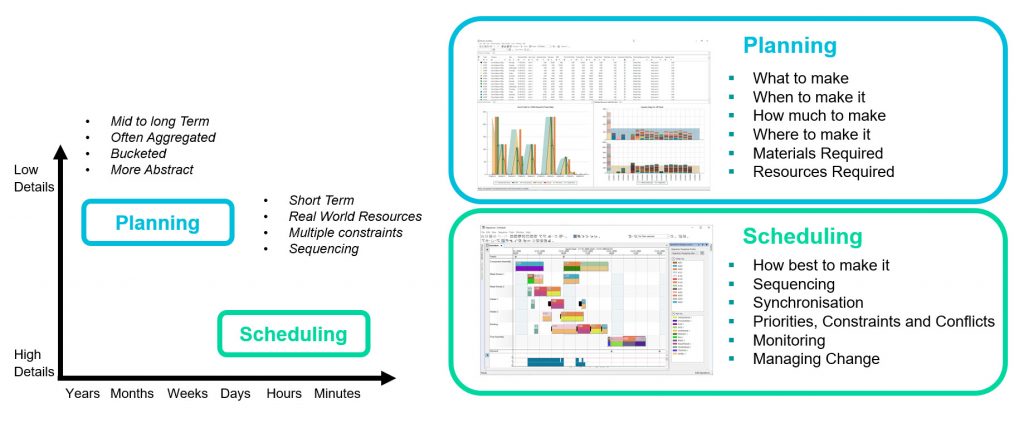

Planning vs. Scheduling